-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

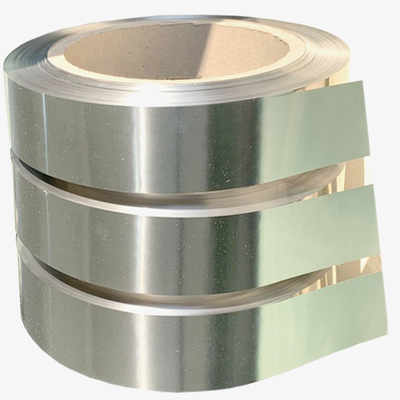

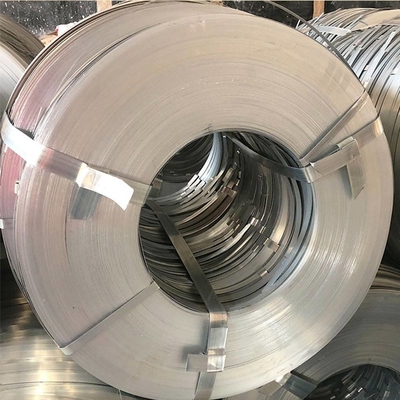

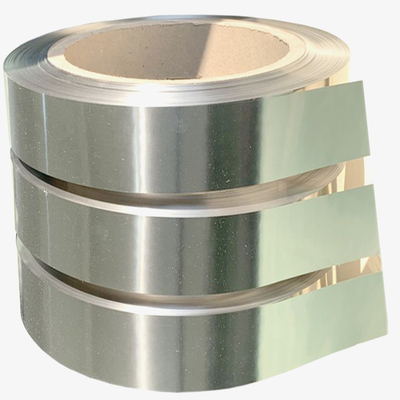

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

309s Cold Rolled Steel Strip 0.5mm Decorations High Temperature Applications

| Place of Origin | China |

|---|---|

| Brand Name | CJ |

| Minimum Order Quantity | 100kg. We also can accept sample order. |

| Packaging Details | Industry standard packaging or according to client's requirement |

| Delivery Time | Fast delievery in7-10 days,up to order quantity |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10,000,000 tons/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | China Manufacturer High Quality Cold Rolled Steel Strip | Thickness | 0.025mm-2.5mm Or As Required |

|---|---|---|---|

| Length | As Required | Technique | Hot Rolled |

| Surface | 2B Or According To Customer Requirement | Thickness Tolerance | ±0.01mm |

| High Light | Cold Rolled Steel Strip 0.5mm,309s Cold Rolled Steel Strip,Stainless Steel Strip 0.5mm |

||

309s Cold Rolled Steel Strip 0.5mm Decorations High Temperature Applications

1. Introduction

The greatest difference between strip and sheet is the width of the coiled product. Any coiled product 24” and wider is considered sheet, while anything under 24” is described as strip. Today's precision slitters can produce widths as small as . 035”, but many applications below .

China Manufacturer High Quality Cold Rolled Steel Strip

Product Name stainless steel strip

| Material | Surface Treatment | Thickness | width |

| 201 | BA | 0.15-0.8mm | 10-800mm |

| 202 | BA | 0.15-0.8mm | 10-800mm |

| 304 | BA | 0.025-0.8mm | 10-800mm |

| 304 | CSP(1/2H,3/4H,H) | 0.08-1.0mm | 10-690mm |

| 301 | CSP(1/2H,3/4H,H,EH) | 0.08-1.0mm | 10-690mm |

| 309S | 2B | 0.08-2.0 | 10-690mm |

| 310S | 2B | 0.08-2.0 | 10-690mm |

| 430 | BA | 0.15-0.8mm | 10-800mm |

| 430 | 1D | 0.15-0.8mm | 10-690mm |

| 430 | 2D | 0.15-0.8mm | 10-690mm |

| 430 | H | 0.08-1.0mm | 10-690mm |

| 409 | HD | 0.15-0.8mm | 10-690mm |

2.Chemical composition and mechanical

200 series:

| level | Chemical composition | Mechanical properties | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 201(1% Nickel) | ≤ 0.15 | ≤ 1.00 | 8~11 | ≤ 0.060 | ≤ 0.030 | 0.9~1.5 | 15~17 | ≤ 0.25 | 1.5~2 | ≥ 310 | ≥ 655 | ≥ 35 | ≤ 105 |

| 202(4% Nickel) | ≤ 0.15 | ≤ 1.00 | 6~9 | ≤ 0.060 | ≤ 0.030 | 3.5~5 | 15~17 | ≤ 0.25 | 1.5~2 | ≥ 260 | ≥ 620 | ≥ 40 | ≤ 100 |

300 series:

| level | Chemical composition | Mechanical properties | ||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 304 | ≤ 0.08 | ≤ 0.75 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 8~10 | 18~20 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 90 | |

| 301 | ≤ 0.15 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 6~8 | 16~18 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 95 | |

| 316 | ≤ 0.08 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 10~14 | 16~18 | 2~3 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 90 |

| 316L | ≤ 0.03 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 12~15 | 16~18 | 2~3 | ≥ 170 | ≥ 480 | ≥ 40 | ≤ 95 |

400 series:

| level | Chemical composition | Mechanical properties | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 430 | ≤ 0.12 | ≤ 1.00 | ≤ 1 | ≤ 0.040 | ≤ 0.030 | 16~18 | ≥ 450 | ≥ 205 | ≥ 22 | ≤ 88 | |||

3.Product Show

![]()

![]()