-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

Polishing Forged Shaft 4340 Stainless Steel Square Rod Cold Drawn

| Place of Origin | China |

|---|---|

| Brand Name | Chengjiu |

| Minimum Order Quantity | 1tons. We also can accept sample order. |

| Price | $500- $5000 / ton (FOB) |

| Packaging Details | Standard Seaworthy Packing |

| Delivery Time | Within 15-30 workdays after receiving deposit or L/C |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1800 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Stainless Steel Forging | Material | 304 316 310 |

|---|---|---|---|

| Size | Non-standard Custom | Subsequent Deep Processing | Welding, Decoiling, Punching, Cutting |

| Heat Treatment | Solid Solution, Aging | Delivery Date | 10-25 Working Days |

| High Light | 4340 Forged Shaft,Stainless Steel Square Rod 4340,Forged Shaft Polishing |

||

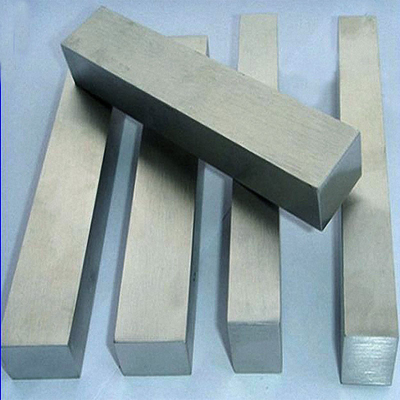

Polishing Forged Shaft 4340 Stainless Steel Square Rod Cold Drawn

1. 4340 Steel Introduction

AISI 4340 steel is a medium carbon, low alloy steel known for its toughness and strength in relatively large sections. AISI 4340 is also one kind of nickel chromium molybdenum steels. 4340 alloy steel is generally supplied hardened and tempered in the tensile range of 930 - 1080 Mpa. Pre hardened and tempered 4340 steels can be further surface hardened by flame or induction hardening and by nitriding. The 4340 steel has good shock and impact resistance as well as wear and abrasion resistance in the hardened condition. AISI 4340 steel properties offer good ductility in the annealed condition, allowing it to be bent or formed. Fusion and resistance welding is also possible with our 4340 alloy steel. AISI 4340 material is often utilized where other alloy steels do not have the hardenability to give the strength required. For highly stressed parts it is excellent choice. AISI 4340 alloy steel can also be machined by all customary methods.

2. 4340 Steel Equivalent

| Country | Japan | Germany | Britain | USA |

| Standard | JIS G4103 | EN10250 | BS970 | ASTM A29 |

| Grade | SNCM439 | 36CrNiMo4/1.6511 | EN24/817M40 | 4340 |

3. 4340 Steel Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | 0.035 | 0.04 | 0.7-09 | 0.2-0.3 | 1.65-2.0 |

| 36CrNiMo4 | 0.32-0.4 | 0.4 | 0.5-0.8 | 0.035 | 0.035 | 0.9-1.2 | 0.15-0.3 | |

| EN24 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | 0.035 | 0.04 | 1.0-1.4 | 0.2-0.35 | 1.3-1.7 |

| SNCM439 | 0.36-0.43 | 0.15-0.35 | 0.6-0.9 | 0.03 | 0.03 | 0.6-1.0 | 0.15-0.3 | 1.6-2.0 |

4. 4340 Steel Available Sizes

| Cold Draw Square Bar | |||||||

| Size (mm) |

Length (m) |

Size (mm) |

Length (m) |

Size (mm) |

Length (m) |

Size (mm) |

Length (m) |

5x5 |

Max 12 | 12x12 | Max 12 | 30x30 | Max 12 | 50x50 | Max 12 |

6x6 |

Max 12 | 15x15 | Max 12 | 35x35 | Max 12 | 55x55 | Max 12 |

8x8 |

Max 12 | 20x20 | Max 12 | 40x40 | Max 12 | 60x60 | Max 12 |

10x10 |

Max 12 | 25x25 | Max 12 | 45x45 | Max 12 | ||

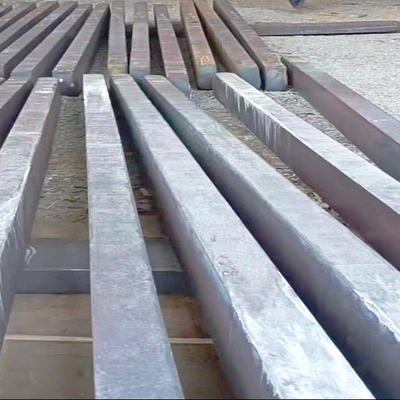

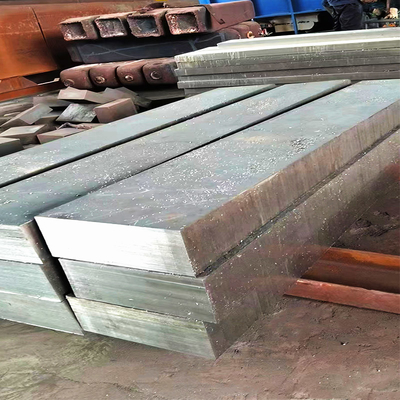

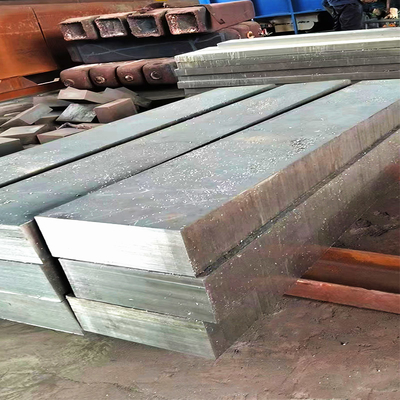

3. Product show

![]()

![]()