-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

Forging Square Stainless Steel 3mm 17 4ph Hot Rolled Forged Steel Shaft

| Place of Origin | China |

|---|---|

| Brand Name | Chengjiu |

| Model Number | 304、201、316、316L、410、2205、2507、309 |

| Minimum Order Quantity | 1ton. We also can accept sample order. |

| Price | bargaining |

| Packaging Details | According to the customers' requirement |

| Delivery Time | Within 15-30 workdays after receiving deposit or L/C |

| Payment Terms | L/C, T/T, Western Union, D/A, D/P, MoneyGram |

| Supply Ability | 5000 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Nname | Stainless Steel Forging17-4PH | Material | 17-4pH Precipitate Hardened Type Steel With Copper |

|---|---|---|---|

| Heat Treatment | Annealing | Process | Press Forging |

| High Light | 17 4ph Stainless Steel 3mm,3mm Forged Steel Shaft,Forged Steel Shaft 17 4ph |

||

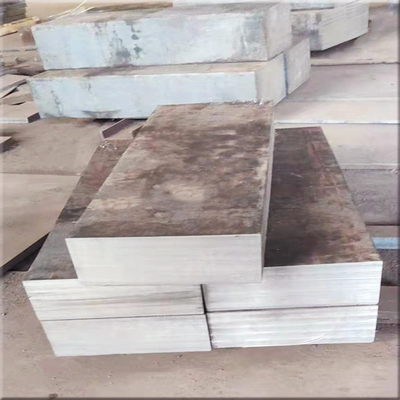

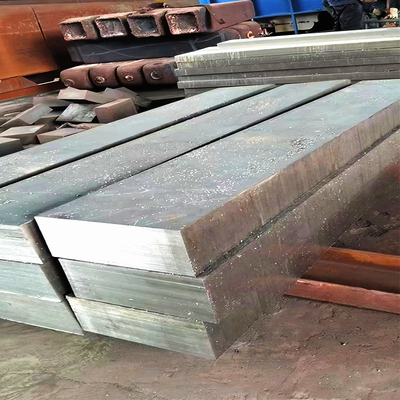

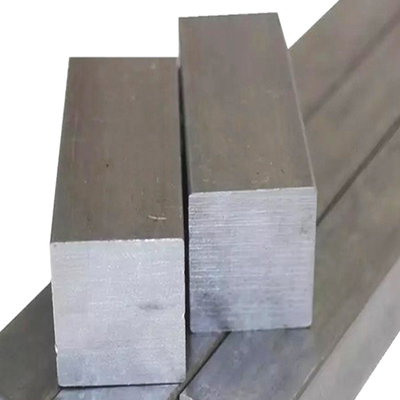

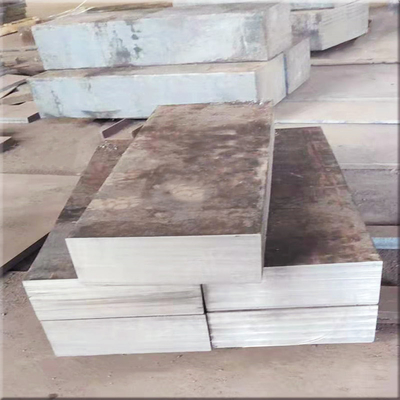

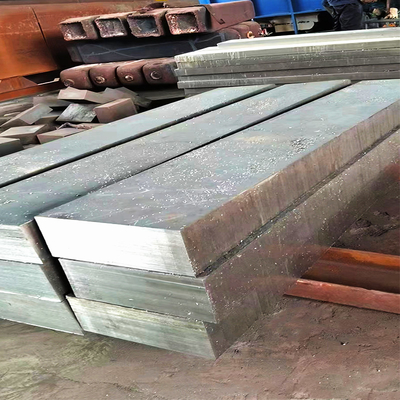

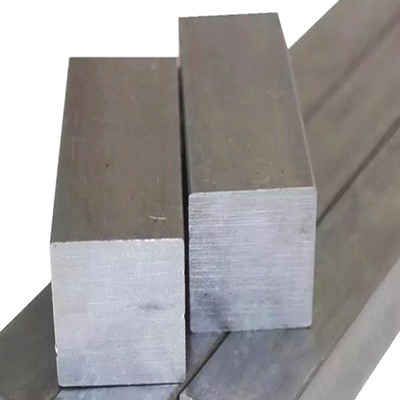

Forging Square Stainless Steel 3mm 17 4ph Hot Rolled Forged Steel Shaft

1. Introduction

The deformation resistance of stainless steel at high temperature is relatively large, therefore, forging stainless steel needs to use a larger tonnage of equipment and wear resistant mold materials. The high temperature resistance of stainless steel is between nickel-based superalloy and general alloy structural steel, and the surface rises with the increase of the deformation degree, so too much deformation degree can not be used.

2. Chemical composition and mechanical Properties

| Chemical composition | |||||||||

| specifications | C | Mn | Si | Cr | Ni | P | S | Cu | Nb+Ta |

| 17-4PH(SUS630)UNS number S17400 | ≤0.07 | ≤1.00 | ≤1.00 | 15.5~17.5 | 3.0~5.0 | ≤0.04 | ≤0.03 | 3.0~5.0 | 0.15~0.45 |

3. Mechanical properties

Tensile strength σB (MPa) : 480℃ aging,≥1310; 550 ℃ ageing, p 1060; 580 ℃ ageing, p 1000; 620 ℃ ageing, p. 930

Conditional yield strength σ0.2 (MPa) : 480℃ aging,≥1180; 550 ℃ ageing, p 1000; 580 ℃ ageing, p 865; 620 ℃ ageing, p. 725

Elongation δ5 (%) : aging at 480℃,≥10; 550 ℃ ageing, 12 or higher; 580 ℃ ageing, 13 or higher; 620 ℃ ageing, 16 or higher

Section shrinkage ψ (%) : 480℃ aging,≥40; 550 ℃ ageing, 45 or higher; 580 ℃ ageing, 45 or higher; 620 ℃ ageing, 50 or more

Hardness: solid solution,≤363HB and ≤38HRC; Aging at 480℃,≥375HB and ≥40HRC; Aged at 550℃,≥331HB and ≥35HRC; Aging at 580℃,≥302HB and ≥31HRC; Aged at 620℃,≥277HB and ≥28HRC

4. Product Show

![]()

![]()