-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

Free Cutting Forged Shaft St52 Stainless Steel Sleeve Hot Forging Wear Resistant

| Place of Origin | China |

|---|---|

| Brand Name | Chengjiu |

| Model Number | 304 304L 306 321 2520 2205 2507 316L |

| Minimum Order Quantity | 1tons. We also can accept sample order. |

| Price | $500- $5000 / ton (FOB) |

| Packaging Details | Standard Seaworthy Packing |

| Delivery Time | Within 15-30 workdays after receiving deposit or L/C |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1800 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | 310 Stainless Steel Forging | Material | 304 316 310 |

|---|---|---|---|

| Size | Non-standard Custom | Heat Treatment | Solid Solution, Aging |

| Delivery Date | 10-25 Working Days | Subsequent Deep Processing | Welding, Decoiling, Punching, Cutting |

| Highlight | Stainless Steel Sleeve St52,St52 Forged Shaft,Wear Resistant Forged Shaft |

||

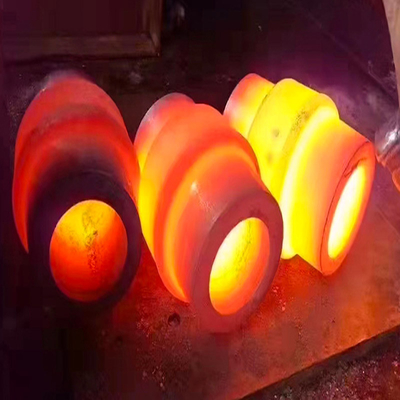

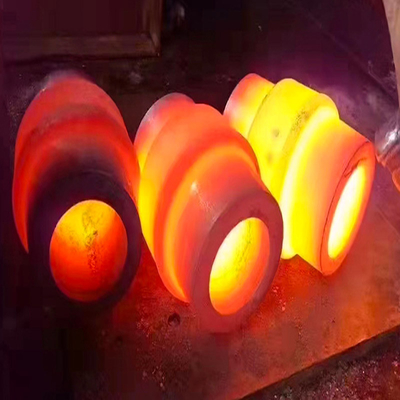

Free Cutting Stainless Steel Sleeve St52 Forged Shaft Hot Forging Wear Resistant

1. Introduction

The deformation is too small after high temperature return to the furnace. Through the analysis of the causes and parts of the defects, the result of our analysis is that when the forging team is about to form these stainless steel forgings, they are installed back into the high temperature furnace for heating. After a short period of heat preservation (because the grain growth inside is not too serious), clamped out only flat end face, basically no rolling outer circle. As a result, the grains of a certain thickness on the inner and outer surfaces grow and merge at high temperatures. This defect can not be eliminated by heat treatment after forging (it is not that there is no defect near the inner and outer surface, but there is a flaw blind area under the probe). See the above defect cause analysis, we should understand: why repeatedly emphasize that the forging after a fire, never allow no deformation or small deformation.

2. Product Show

![]()

![]()