-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

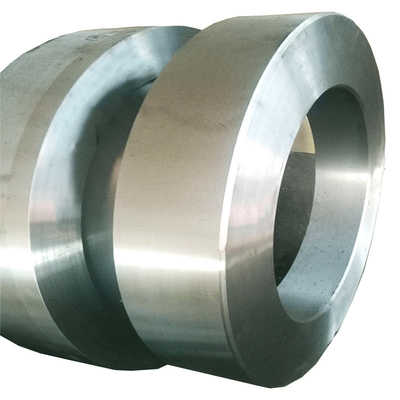

OEM Customized Forged Shaft Cold Forging Stainless Steel Ring 321 309S 904L

| Place of Origin | China |

|---|---|

| Brand Name | Chengjiu |

| Model Number | 201、304、316、316L、2205、2507 |

| Minimum Order Quantity | 1tons. We also can accept sample order. |

| Price | $500- $5000 / ton (FOB) |

| Packaging Details | Standard Seaworthy Packing |

| Delivery Time | Within 15-30 workdays after receiving deposit or L/C |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1800 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | 904L Stainless Steel Forging | Material | 304 316 310 316L |

|---|---|---|---|

| Size | Non-standard Custom | Heat Treatment | Solid Solution, Aging |

| Subsequent Deep Processing | Welding, Decoiling, Punching, Cutting | Delivery Date | 10-25 Working Days |

| High Light | Forged Shaft Cold Forging,Forged Shaft 904L,904L Forging Stainless Steel |

||

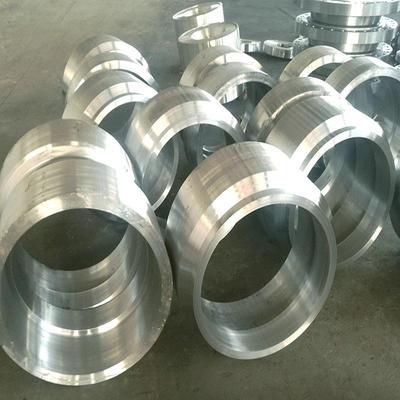

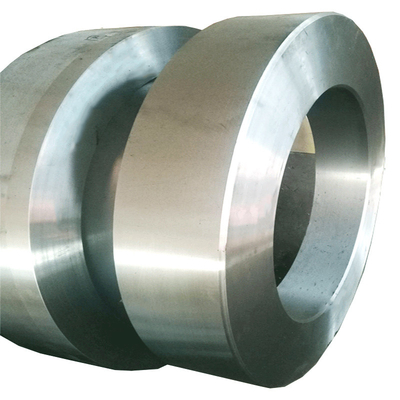

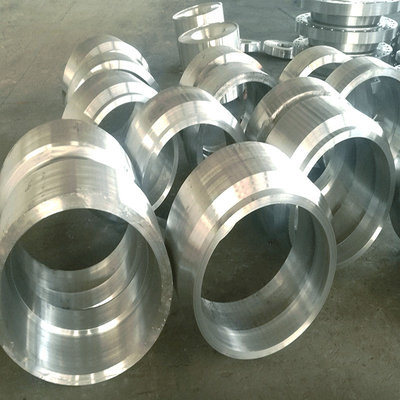

OEM Customized Forged Shaft Cold Forging Stainless Steel Ring 321 309S 904L

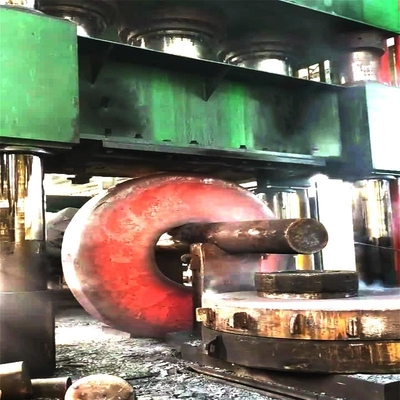

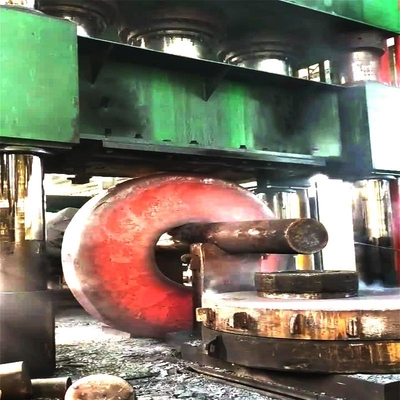

1. Introduction

he purpose of heating in the forging process of stainless steel forgings is to reduce the forging deformation force and improve the metal plasticity. But heating also brings a series of problems, such as oxidation, decarbonization, overheating and overburning. Accurate control of initial and final forging temperature has great influence on product structure and performance.

Flame furnace heating has the advantages of low cost and strong applicability, but the heating time is long, easy to produce oxidation and decarbonization, and the working conditions need to be constantly improved. Induction heating has the advantages of rapid heating and less oxidation, but it has poor adaptability to product shape, size and material change.

2. Product Show

![]()