-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

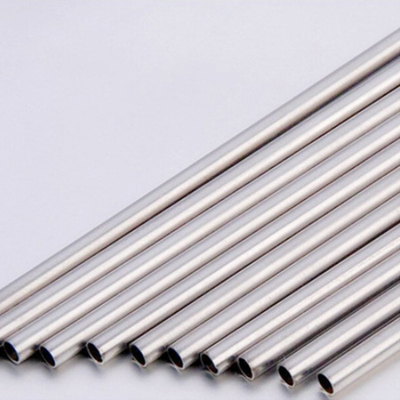

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

Good Machinability Hastelloy Alloy C22 With Tensile Strength Up To 1

| Place of Origin | jiangsu china |

|---|---|

| Brand Name | CJ |

| Model Number | C276 B3 C22 B2 |

| Minimum Order Quantity | 1KG |

| Price | Negotiable |

| Packaging Details | Standard export packaging or Negotiable |

| Delivery Time | Specific according to the product |

| Payment Terms | 30% advance payment+70% final payment |

| Supply Ability | 5000 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Electrical Resistivity | 1.2 μΩ-cm | Machinability | Good |

|---|---|---|---|

| Yield Strength | Up To 1,000 MPa | Material | Hastelloy |

| Modulus Of Elasticity | 200 GPa | Hardness | Up To 400 HB |

| Thermal Conductivity | 13.9 W/m-K | Density | 8.69 G/cm3 |

| High Light | Good Machinability Hastelloy Alloy,Hastelloy C22 Alloy |

||

Product Description:

Hastelloy is a range of Nickel-based alloys, with a wide range of applications in many industries. The most popular alloys are Hastelloy Alloy X, Hastelloy Alloy G-35, Hastelloy Alloy X-750 and Hastelloy Alloy B-3. These alloys possess excellent resistance to corrosion, good machinability, high hardness up to 400HB, excellent formability and low thermal expansion of 12.9µm/m-K. Hastelloy is widely used in chemical processing, pollution control, power generation, and other industries and applications where corrosion resistance is important.

Features:

- Product Name: Hastelloy Material

- Hardness: Up To 400 HB

- Tensile Strength: Up To 1,200 MPa

- Elongation: Up To 45%

- Corrosion Resistance: Excellent

- Yield Strength: Up To 1,000 MPa

- Alloys: Hastelloy Alloy B2, Hastelloy Alloy B2, Hastelloy Alloy C276, Hastelloy Alloy C4, Hastelloy Alloy C22

Technical Parameters:

| Property | Value |

|---|---|

| Material | Hastelloy Alloy C4, Hastelloy Alloy B2, Hastelloy Alloy C276 |

| Yield Strength | Up To 1,000 MPa |

| Tensile Strength | Up To 1,200 MPa |

| Elongation | Up To 45% |

| Hardness | Up To 400 HB |

| Weldability | Excellent |

| Formability | Excellent |

| Thermal Conductivity | 13.9 W/m-K |

| Thermal Expansion | 12.9 µm/m-K |

| Melting Point | 1370-1443°C |

Applications:

CJ Hastelloy Alloy C4, C276, B2, B3 and C22 materials are nickel-based alloys that offer excellent corrosion resistance in a wide range of industrial applications. These materials are widely used in the chemical processing, pharmaceutical, oil and gas, and pulp and paper industries. The Hastelloy alloys are highly resistant to chlorine and organic acids, and are often used in heat exchangers and other parts exposed to harsh environments. CJ Hastelloy alloys have a high thermal expansion of 12.9 µm/m-K, weldability of Excellent, and density of 8.69 G/cm3, making them ideal for a variety of applications. CJ Hastelloy alloys also have excellent electrical resistivity, with a value of 1.2 μΩ-cm. CJ Hastelloy Alloy materials are available in minimum order quantities of 1KG with negotiable prices. Our standard export packaging ensures safe delivery to the customer within a specified time frame, and payments can be arranged as 30% advance payment+70% final payment. We have a monthly production capacity of 5000 tons and are committed to providing top-quality products and service to our customers.

Customization:

Brand Name: CJ

Model Number: C276,B3,C22,B2

Place of Origin: jiangsu china

Minimum Order Quantity: 1KG

Price: Negotiable

Packaging Details: Standard export packaging or Negotiable

Delivery Time: Specific according to the product

Payment Terms: 30% advance payment+70% final payment

Supply Ability: 5000 tons/month

- Weldability: Excellent

- Electrical Resistivity: 1.2 μΩ-cm

- Density: 8.69 G/cm3

- Tensile Strength: Up To 1,200 MPa

- Machinability: Good

Packing and Shipping:

Hastelloy Material Packaging and Shipping:

- The material will be packaged in plastic or metal containers with lids or seals that are securely affixed to the container.

- The containers will then be placed in cardboard boxes or crates, which will be sealed and labeled.

- The materials will be shipped via ground, air, or sea freight, depending on the desired destination and urgency of delivery.

- The shipments will be tracked throughout the shipping process to ensure safe delivery.