-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

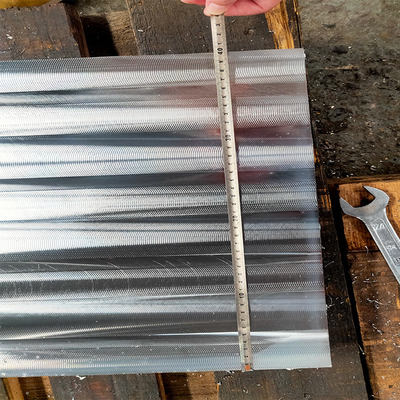

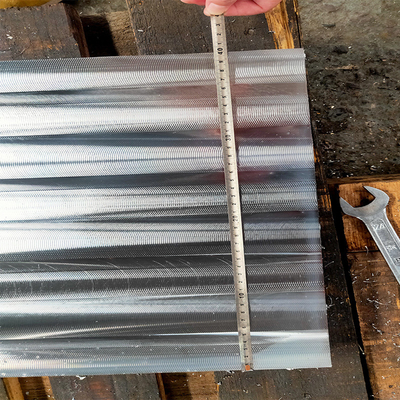

Stainless Steel Wire Mesh

-

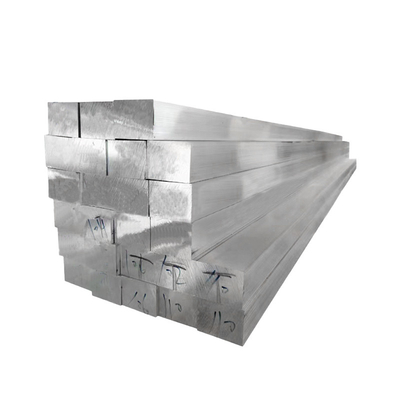

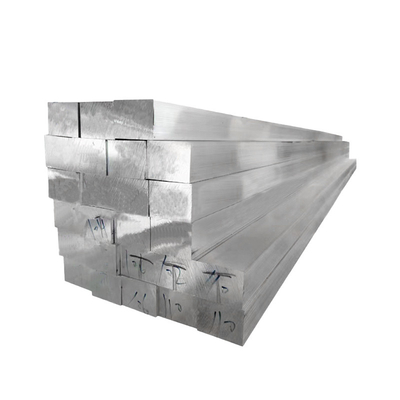

Stainless Steel Bar

-

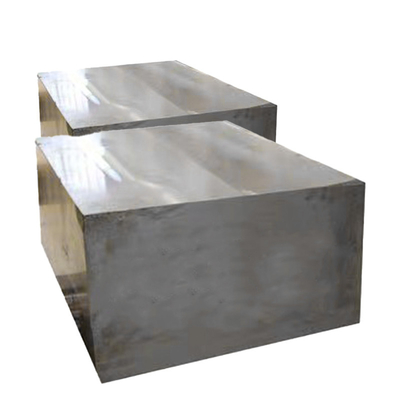

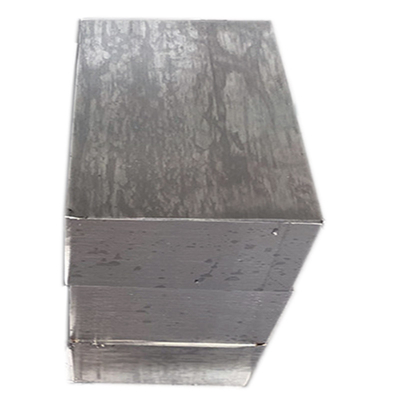

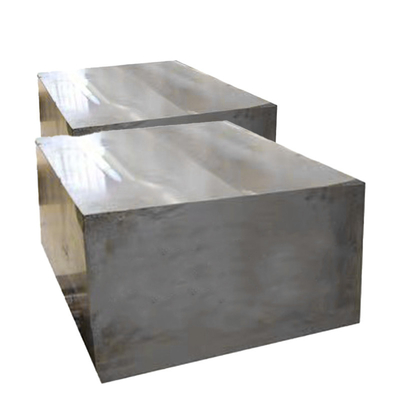

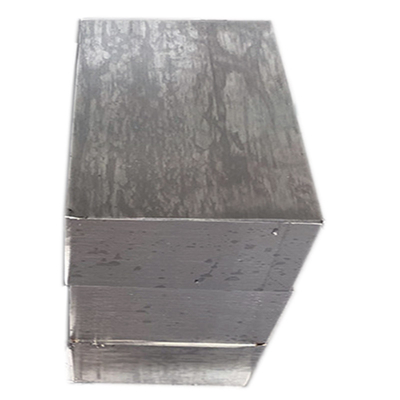

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

Heat Treatment Annealing Metal Forging Process 1200-1400°C

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Die Material | Alloy Steel | Surface Treatment | Polishing |

|---|---|---|---|

| Forging Method | Hot Forging | Process Type | Metal Forging |

| Die Type | Open Die | Material | Steel |

| Forging Pressure | 200-500 MPa | Material Quality | Customized |

Features:

- Product Name: Metal Forging Process

- Forging Pressure: 200-500 MPa

- Material: Steel

- Process Type: Metal Forging

- Forging Speed: 0.5-2 M/s

- Hardness: Negotiable

- Forge Metal Procedure: Forging metal components to desired shape and size with extreme pressure

- Forged: Metal forging process that produces strong and precise components

- Forged Link: Joining two metal components together using the metal forging process

Technical Parameters:

| Parameters | Details |

|---|---|

| Lubrication | Oil |

| Forging Speed | 0.5-2 M/s |

| Process Type | Metal Forging |

| material quality | Customized |

| Die Surface Treatment | Nitriding |

| Material | Steel |

| Die Type | Open Die |

| Heat Treatment | Annealing |

| Die Material | Alloy Steel |

| Forging Method | Hot Forging |

| Forged Products | Forged Shaft, Forged Ring, Forged Flange, Forged Shaft, Forged Pipe |

Applications:

CJ provides a metal forging process that uses a metal forge technique to create unique forged shapes and components. The forged ring or component is created by applying high pressure to a heated metal blank. The forging temperature of the metal blank is controlled within a range of 1200-1400°C, and the forging pressure used is 200-500 MPa. The die material used to create the forged component is typically an alloy steel, and the surface treatment of the component can be customized to meet the needs of the customer. The material quality of the component can also be customized according to the customer's requirements. The minimum order quantity for the Metal Forging Process is 1KG, and the price is negotiable. The delivery time is determined specifically according to the product requirements, and the payment terms are 30% advance payment+70% final payment. Thanks to CJ's advanced technology and production capacity, the supply ability of the Metal Forging Process is up to 5000 tons/month.

Customization:

Brand Name: CJ

Place of Origin: Jiangsu, China

Minimum Order Quantity: 1KG

Price: Negotiable

Packaging Details: Standard export packaging or Negotiable

Delivery Time: Specific according to the product

Payment Terms: 30% advance payment+70% final payment

Supply Ability: 5000 tons/month

Surface Treatment: Polishing

Forging Speed: 0.5-2 M/s

Forging Temperature: 1200-1400°C

Forging Method: Hot Forging

Die Surface Treatment: Nitriding

CJ offers customized metal forging process to meet the needs of customers. With our high-quality products and reliable services, we can guarantee that your metal forging process will be efficient and accurate. We offer a wide range of forging services, including forge metal procedure, forged link procedure, and much more.

Our customized metal forging process meets the highest standards of quality and accuracy. We use the best materials and technologies to ensure that our services are perfect for your needs. Our forging speed is between 0.5-2 M/s and the forging temperature is between 1200-1400°C. We also provide surface treatment, such as polishing, and die surface treatment, such as nitriding.

Our minimum order quantity is 1KG and the price is negotiable. We also accept custom orders and provide standard export packaging or negotiable packaging. Delivery time is specific according to the product and we accept payment terms of 30% advance payment+70% final payment. We have a supply ability of 5000 tons/month.

For more information about our customized metal forging process, please contact us today.

Support and Services:

At

We offer a range of services to ensure that your metal forging process is running smoothly and efficiently. These include troubleshooting and repair of equipment, testing and analysis of materials, and inspection and certification of components. Our team can provide training for personnel working in the metal forging process, as well as advice on safety procedures and quality control.

In addition, we offer a range of services related to the metal forging process, including process control and optimization, process validation, and process monitoring. We also provide technical support and advice on process design and optimization, as well as guidance on best practices for metal forging.

Our expert team of engineers and technicians is available to help you with any questions you may have regarding the metal forging process. We are dedicated to providing the highest level of technical support and service. Contact us today to discuss your needs and to learn more about our services.

Packing and Shipping:

The packaging and shipping process for Metal Forging Process is quite straightforward. All products are wrapped in protective materials before being packed into boxes or crates according to their size and weight. The boxes or crates are then securely sealed and labeled with the contents and shipping information. The boxes or crates are then loaded into a truck or shipping container for transport.

Once the products have arrived at their destination, they will be unloaded and then inspected to make sure they have arrived in good condition. The products will then be unpacked and stored until they are ready to be used.

FAQ:

- Q1: What is Metal Forging Process?

- A1: Metal Forging Process is a forming process that involves applying compressive forces to a workpiece to deform it, and create a desired geometric change of the metal part's shape. CJ's Metal Forging Process is manufactured in Jiangsu China, with minimum order quantity of 1 kg and price negotiable.

- Q2: What is the delivery time of CJ's Metal Forging Process?

- A2: Delivery time of CJ's Metal Forging Process is specific according to the product.

- Q3: What are the payment terms of CJ's Metal Forging Process?

- A3: Payment terms of CJ's Metal Forging Process is 30% advance payment+70% final payment.

- Q4: How much can CJ's Metal Forging Process supply each month?

- A4: CJ's Metal Forging Process can supply up to 5000 tons per month.

- Q5: What kind of packaging does CJ's Metal Forging Process use?

- A5: CJ's Metal Forging Process uses standard export packaging or negotiable.