-

Cold Rolled Stainless Steel Sheets

-

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

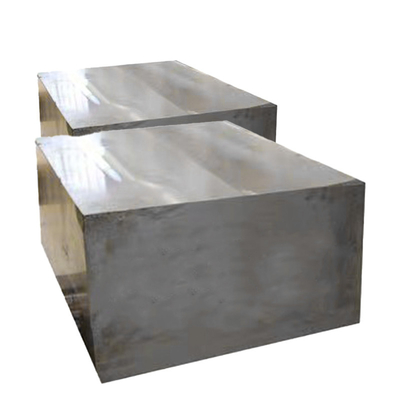

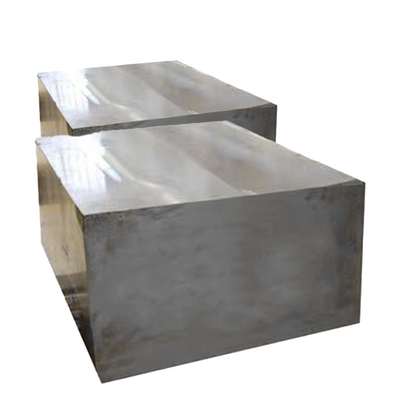

Open Die Hot Forging Alloy Steel Metal Forging Process

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material Quality | Customized | Forging Temperature | 1200-1400°C |

|---|---|---|---|

| Die Surface Treatment | Nitriding | Heat Treatment | Annealing |

| Surface Treatment | Polishing | Inspection | Ultrasonic Testing |

| Die Material | Alloy Steel | Lubrication | Oil |

Features:

- Product Name: Metal Forging Process

- Forging Pressure: 200-500 MPa

- Die Type: Open Die

- Inspection: Ultrasonic Testing

- Surface Treatment: Polishing

- Die Material: Alloy Steel

- Product Features: Forged Ring, Metal Forge Technique, Forged Disc, Forged Bar

Technical Parameters:

| Attributes | Value |

|---|---|

| Inspection | Ultrasonic Testing |

| Hardness | Negotiable |

| Forging Speed | 0.5-2 M/s |

| Material | Steel |

| Surface Treatment | Polishing |

| Material quality | Customized |

| Forging Pressure | 200-500 MPa |

| Process Type | Metal Forging |

| Forging Temperature | 1200-1400°C |

| Lubrication | Oil |

| Forging Technique | Metal Forge |

| Quality Assurance | Forged |

Applications:

Metal forging is a process of shaping metal by hammering, pressing, or rolling. It is a popular manufacturing technique for producing metal components with precise shapes and sizes. CJ is a well-known brand for its metal forging process with Chinese origin. The metal forging procedure consists of hammering, pressing, or rolling of metal to create a desired shape and size. The process can be used to create components from a variety of materials, including steel, and it is suitable for mass production.

The negotiable pricing and standard export packaging of CJ’s metal forging process make it a cost-effective solution for many industrial and commercial applications. The specific delivery time is determined according to the product while the payment terms require a 30% advance payment and 70% final payment. Additionally, the company has the capability to supply up to 5000 tons of metal forging products each month.

The steel material used for metal forging is subject to an ultrasonic testing to ensure the highest quality. The process also involves annealing heat treatment for improved strength and durability. The components can be formed with open die and hot forging methods, which are suitable for mass production and high-volume orders.

CJ’s metal forging process is a reliable and cost-effective solution for many industrial and commercial applications. The company offers negotiable pricing, standard export packaging, specific delivery time, and payment terms. It also has the capability to supply up to 5000 tons of metal forging products each month. The steel material used for metal forging is subject to an ultrasonic testing and annealing heat treatment for improved strength and durability. The components can be formed with open die and hot forging methods, which are suitable for mass production and high-volume orders.

Customization:

CJ provides customized services for Metal Forging Process, including forged shaft, forge metal procedure, and forged products. Our products come with the following attributes:

- Brand Name: CJ

- Place of Origin: Jiangsu, China

- Minimum Order Quantity: 1KG

- Price: Negotiable

- Packaging Details: Standard export packaging or Negotiable

- Delivery Time: Specific according to the product

- Payment Terms: 30% advance payment+70% final payment

- Supply Ability: 5000 tons/month

- Die Material: Alloy Steel

- Surface Treatment: Polishing

- Die Type: Open Die

- Forging Temperature: 1200-1400°C

- Die Surface Treatment: Nitriding

Support and Services:

Our technical support and service for Metal Forging Process includes:

- Providing installation and maintenance instructions for Metal Forging Process.

- Providing support for troubleshooting and debugging.

- Providing customer service for any questions or concerns.

- Providing product updates and upgrades.

- Providing technical advice for the best use of the product.

Packing and Shipping:

Metal Forging Process Packaging and Shipping:

- The metal forging process products shall be carefully packed in containers with sufficient cushioning material to prevent damage during transport.

- The containers shall be sealed and labeled clearly with the product description.

- The containers shall be shipped by reliable carriers with tracking number.

FAQ:

Metal Forging Process FAQs

Q1: What is the brand name of Metal Forging Process?

A1: The brand name of Metal Forging Process is CJ.

Q2: Where is Metal Forging Process made?

A2: Metal Forging Process is made in Jiangsu, China.

Q3: What is the minimum order quantity of Metal Forging Process?

A3: The minimum order quantity of Metal Forging Process is 1KG.

Q4: How much does Metal Forging Process cost?

A4: The cost of Metal Forging Process is negotiable.

Q5: What is the packaging of Metal Forging Process?

A5: The packaging of Metal Forging Process is either standard export packaging or negotiable.