-

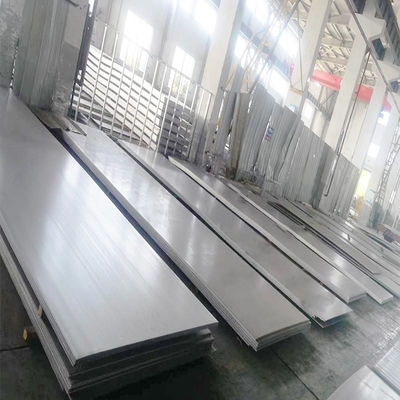

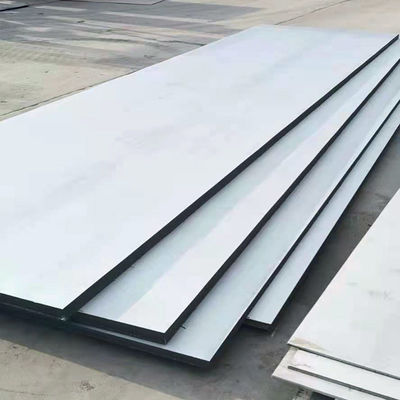

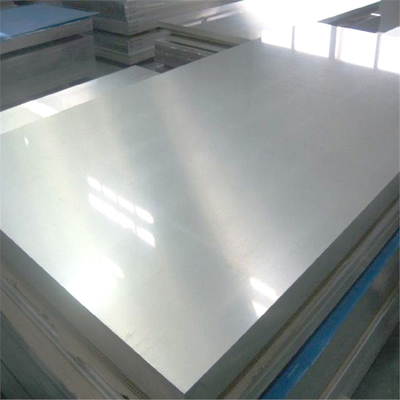

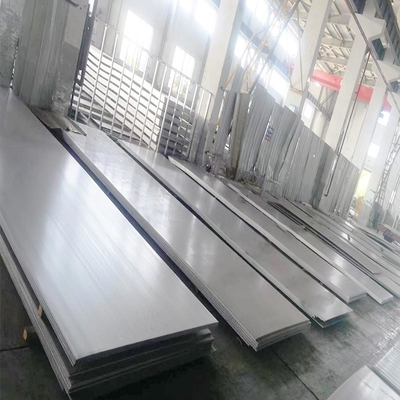

Cold Rolled Stainless Steel Sheets

-

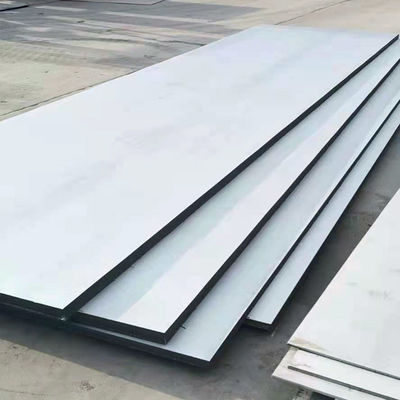

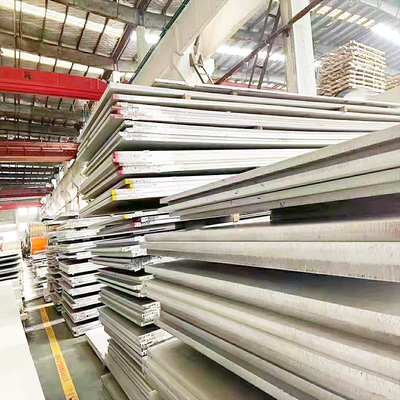

Hot Rolled Stainless Steel Sheets

-

Stainless Steel Round Pipe

-

Stainless Steel Coil Strip

-

Stainless Steel Wire Mesh

-

Stainless Steel Bar

-

Metal Forging Process

-

High Temperature Alloy

-

Corrosion Resisting Alloy

-

Super Austenitic Stainless Steel

-

Incoloy Alloy

-

Nickel Base Alloy

-

Precision Alloy

-

Monel Metal Alloy

-

Hastelloy Material

-

Inconel Special Metals

-

Titanium Alloy Material

-

Resistance Electrothermal Alloy

4X8 Stainless Steel Hot Rolled Plate NO.4 16 Gauge Stainless Steel Sheet

| Place of Origin | China |

|---|---|

| Brand Name | Chengjiu |

| Minimum Order Quantity | 100kg. We also can accept sample order. |

| Price | $1500- $2500 / ton (FOB) |

| Packaging Details | Standard Seaworthy Packing |

| Delivery Time | Within 15-30 workdays after receiving deposit or L/C |

| Payment Terms | L/C, T/T, Western Union, MoneyGram, D/P, D/A |

| Supply Ability | 5000 tons/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Customized Square 0.6mm Cold Rolled Sheet 304 Stainless Steel Plate | Type | Cold Rolled |

|---|---|---|---|

| Standard | ASTM JIS AISI GB DIN EN | Surface Treatment | BA, NO.1, NO.4, 4K, HL, 8K |

| Width | 1000, 1219, 1500, 2000, 2500, 3000mm, Etc | Application | Widely Used In High Temperature Electrical Industry, Medical Equipment, Construction, Chemistry, Food Industry, Agriculture, Marine Components And Other Fields. It Is Also Suitable For Food And Beverage Packaging, Kitchen Supplies, Trains, Airplanes |

| Highlight | 4X8 Stainless Steel Hot Rolled Plate,16 Gauge Stainless Steel Sheet 4X8,NO.4 16 Gauge Stainless Steel Sheet |

||

4X8 Stainless Steel Hot Rolled Plate NO.4 16 Gauge Stainless Steel Sheet

1. Introduction

Stainless Steel Surface Treatments

1D—The surface has discontinuous particles, which is also called matte. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D—Slightly shiny silver-white. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

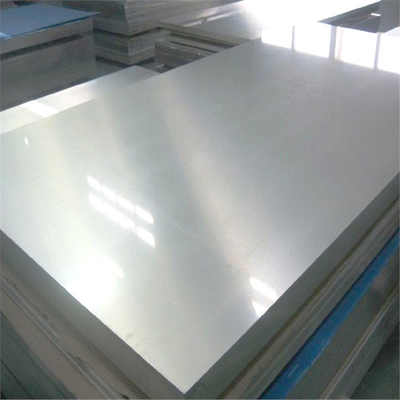

2B—Silver white and better gloss and flatness than 2D surface. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

BA—The surface gloss is excellent and has a high reflectivity, just like the mirror surface. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenched and tempered rolling.

No.3—has better gloss and rough surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 100 ~ 120 abrasive materials.

No.4—has better gloss and fine lines on the surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 150 ~ 180 abrasive materials.

HL—Silver gray with hair streaks. Processing technology: Polish the 2D product or 2B product with a suitable size of abrasive material to make the surface appear continuous grain.

MIRROR Machining —is in a mirror state. Processing technology: 2D or 2B products are ground and polished to a mirror effect with a suitable abrasive material.

2. Product Show

![]()

![]()